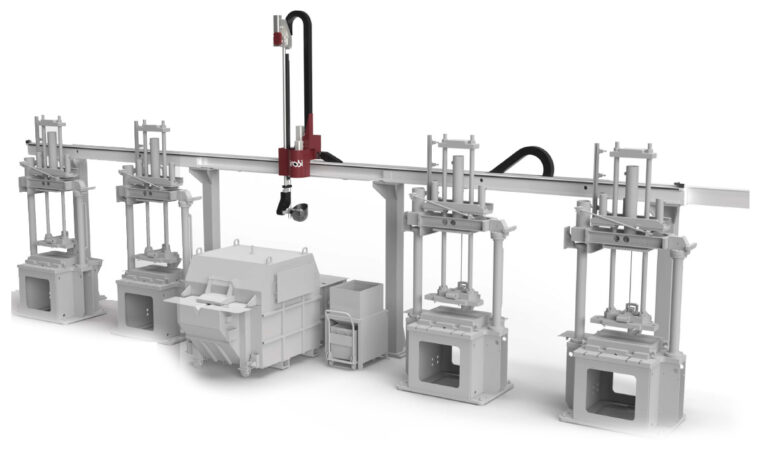

AUTOMATION SYSTEM

FOR DIE-CASTING

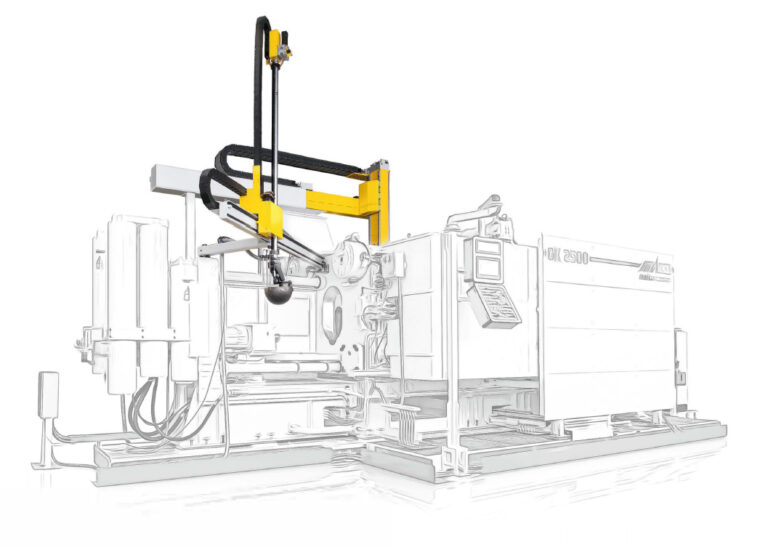

SPRAYERS

The correct lubrication and drying of the die is decisive for the casting cycle and the production of a quality part.

The movement is provided by a PLC-controlled brushless motor associated with a gearbox with rack and pinion transmission in treated steel. Sliding is carried out by means of guides and recirculating ball carriages with prismatic profile.

The programmable control equipment via touch-screen keyboard allows the positioning with decimal precision of 50 different lubrication positions, with the possibility of storing programmes and die data.

“LUBRIFOND” SERIES SPRAYERS

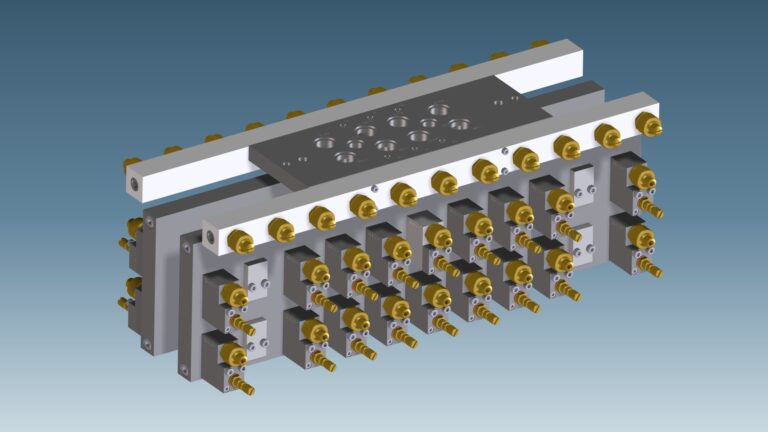

FITTING FOR SPRAYERS

DEDICATED SPRAYING HEADS FOR THE DIFFERENT DIES

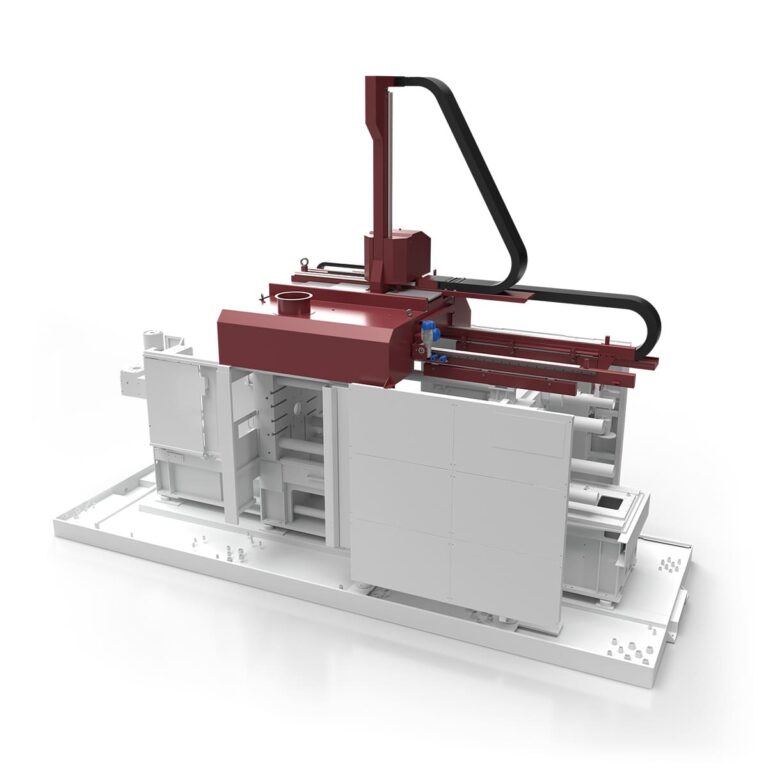

AUTOMATIC LADLES

It is suitable for all aluminium alloys. It allows the dosing and transport of molten metal from the adjacent furnace to the die-casting machine.

The movement of the cup is carried out by means of a closed-loop brushless servomotor that enables to keep constant the quantity of taken metal.

All operating parameters are programmable via touch-screen keyboard.